Traditional screen analysis is not useful for automation. Attempts of creation a screen particle size indicator were undertaken, but the matter was not farther single samples. Stream instruments were necessary. Ultrasonic devices have essential disadvantages. There are necessary to un-magnetic and to gather out an air from a pulp. It essentially complicates and rises a price of the unit.

In the beginning of 60-th years I have paid attention to two circumstances.

By connecting together these two factors and by conducting own researches, I have proved that measuring an average diameter only of large classes, it is possible to have the authentic information on any selected check class in an analyzed pulp.

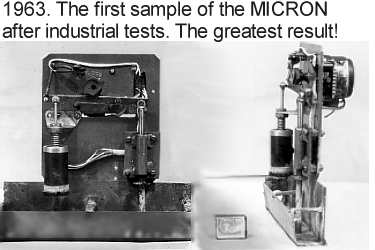

By result of my further searches there was the creation of a direct contact method of particle size measurement and particle size indicator the MICRON.

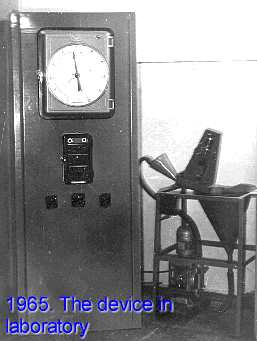

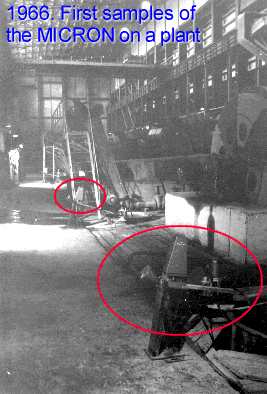

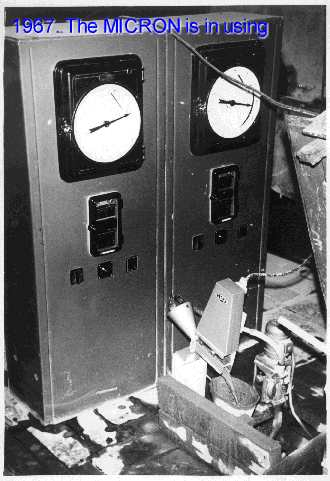

The evolution of the MICRON is indicated in photos.